Colloidal Alumina

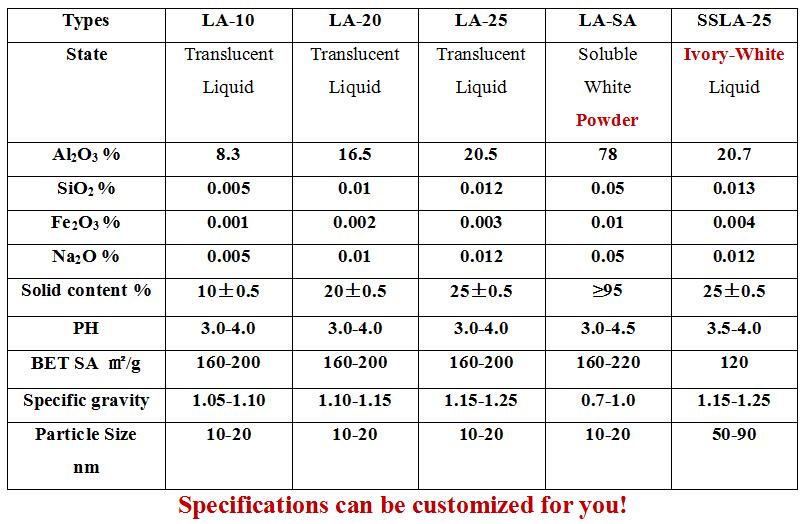

Colloidal Alumina (also called alumina sol) is nanometer aluminum hydroxide particles suspending in deionized water. The normal form is translucent or ivory-white liquid, can be transformed into dry powder through spray drying process, and could become liquid alumina sol again after dissolving in deionized water.

Application & Advantages:

Compared with silicon sol, alumina sol has better purity and could stands higher temperature.By now our clients mainly apply our Colloidal Alumina to below fields:

1. Lithium battery anode materialAs covered agent for the anode material, mainly use LA-10.

2. Antifoggant (for coating, greenhouse plastic film, etc.)Important raw material of plastic greenhouse film antifoggant.

3. Coating of non-stick pan and glazeCompared with colloidal silica, Colloidal Alumina has better adhesion, and can stand higher temperature. After freezing, Colloidal Alumina could be reused after heated over 80℃, while colloidal silica can't be reused anymore. With these advantages, now our clients use Colloidal Alumina to entirely replace colloidal silica in non-stick pan coating field.

4. Coating of Ceramic membraneMainly our clients combine the Colloidal Alumina and colloidal silica with an ratio between Al2O3 and SiO2 from 8:2 to 7:3. This combination has better performance on hardness than solely use colloidal silica.

5. Binder of catalyst carrierColloidal alumina could help shaping carrier form and maintaining its form during calcination.

6. Addition in refractoryColloidal alumina can be added into refractory to increase pressure tolerance and tolerable temperature of the castable. Normally use SSLA-25.

7. Rigidizer for ceramic fiberColloidal Alumina could completely seals dust and fibers on the surface of all cut or sanded fiber boards and shapes. This rigidizer has less tendency to migrate to the surface upon drying, resulting in a more uniform product. Normally use SSLA-25.

8. Addition for textile industry (Acrylic aldehyde, polypropylene, nylon, polyester, wool,etc.)Colloidal Alumina can be used as anti-static additive, and also can significantly enhance the strength and abrasion resistance performance of fiber, can also make the textile looks and feels smoother and brighter.

How to dissolve (for LA-SA):

Please use deionized water( electrical conductivity <5 will be better) to dissolve. The ratio between water and powder depends on the concentration you need, but should not over 30%, or the alumina sol will be sticky as gel. Please gently stir the water while gradually put powder into water when dissolve. Please stay the dissolved liquid for 24 hours before using, to let the alumina particle distribute more evenly.

Packaging

25kg plastic drum with pallet/ 1.1MT IBC Tank for liquid

25kg woven bag/Ton bag for powder

Storage

Liquid alumina sol should not be subjected to temperature of 0℃ or below to avoid freezing. Shelf time 8 months.

Powder alumina sol LA-SA should not be subjected to moisture during storage. Shelf time 2 years.